If you have any question, please contact us

If you have any question, please contact us

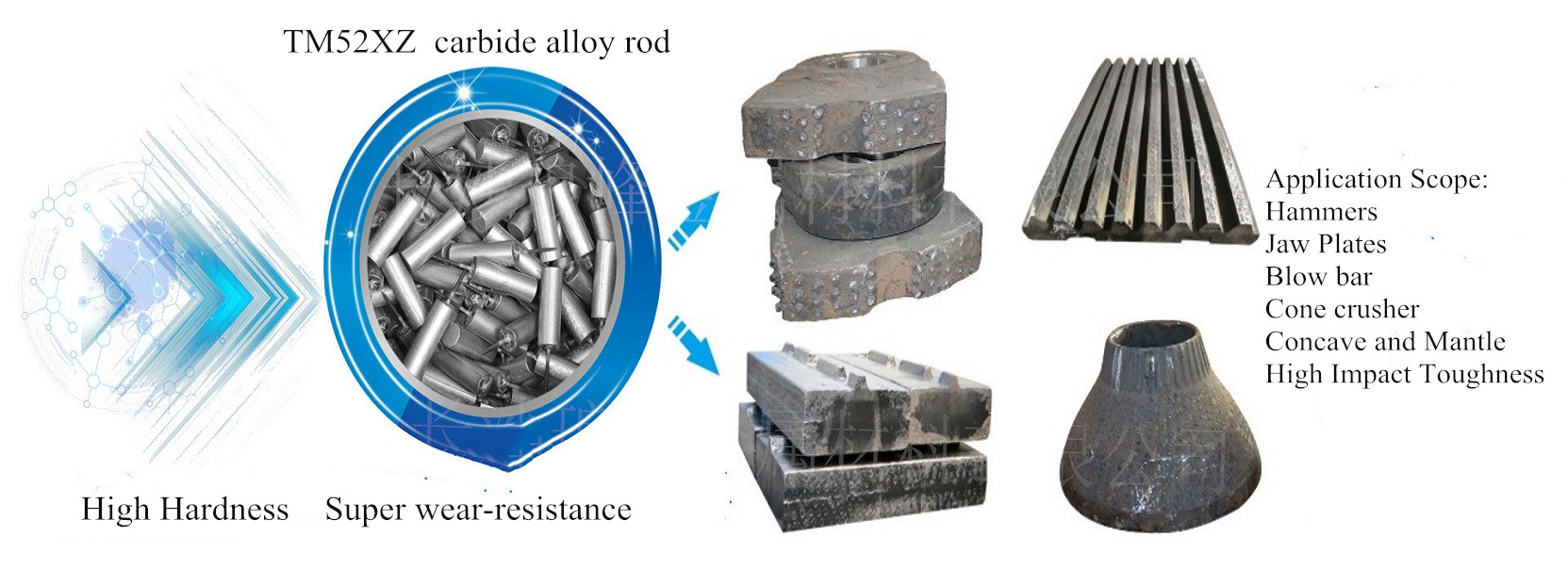

TM52XZ Titanium Carbide Based High Manganese Steel Bonded-Alloy Wear-Resistant Material

Product core advantages:

1.Standardization of production process and process design;

2.Have perfect and intelligent enterprise standards;

3.Independent research and development of high-purity raw materials;

4.Have the core technology of high-end material formulation;

5.Provide free material technology solutions.

Basic product introduction:

TM52XZ Titanium Carbide Based High Manganese Steel Bonded-Alloy with high wear resistance and high toughness, is made of high manganese steel as binder phase, titanium carbide as hard phase. The density is low, 0.8 times that of high manganese steel and 0.42 times that of cemented carbide. It is a high hardness and high toughness wear resistant material, specific resistance: 0.911 Ωmm2/m, elastic modulus: 354 x 103N/mm2, 200-700°C linear expansion coefficient: 11.31 x 10-6/°C, 200-700°C Linear expansion coefficient: 14.43 x 10-6/°C; mainly used in high manganese steel crusher hammer head, concave, mantle, large jaw plate, vertical grinding liner, ball mill liner, blow bars,excavator bucket teeth, feeding chute of blast furnace and coal mill grinding roller.

Product application:

Titanium carbide alloy sintered product metallography:

Titanium carbide alloy sintered product metallography:

Post-wear metallography of titanium carbide:

Product using method:

Product packing:

PHYSICAL:

|

Grade |

TRS (ISO3327) |

Hardness (ISO3878) |

Density (ISO3369) |

Average Grain Size |

Porosities |

|

TM52X |

1600-2000 |

82-83HRA |

6.0-6.3g/cm3 |

2.0 um |

A02B00C00 |

|

TM50X |

1600-2000 |

85-86HRA |

6.0-6.3g/cm3 |

2.0 um |

A02B00C00 |

|

TM48X |

1500-1800 |

88-90HRA |

5.9-6.2g/cm3 |

2.0 um |

A02B00C00 |

CHEMICAL:

|

Grade |

TiC(%) |

Fe+Mn(%) |

Ni+Mo(%) |

Zr+Nb(%) |

Other(%) |

|

TM52X |

46-48 |

46-48 |

2-4 |

1-2 |

2-5 |

|

TM50X |

47-49 |

45-47 |

2-4 |

2-4 |

2-5 |

|

TM48X |

48-50 |

44-46 |

2-4 |

3-5 |

2-5 |